Celebrating 20 Years!

An extension of your engineering team for 20 years.

VACUUM MOTORS TO MANAGE OUTGASSING

OBJECTIVE: When working in the cleanroom environments, outgassing needs to be minimized, or avoided altogether.

CUSTOMER CHALLENGE

Outgassing occurs when gasses and particles that are trapped inside paints, coatings, and greases, are released into the environment and introduce unwanted contaminants. Vacuum rated stepper motors must be designed using low-outgassing materials in order to minimize the outgassing problem, which makes it ideal for cleanroom environments..

SOLUTION

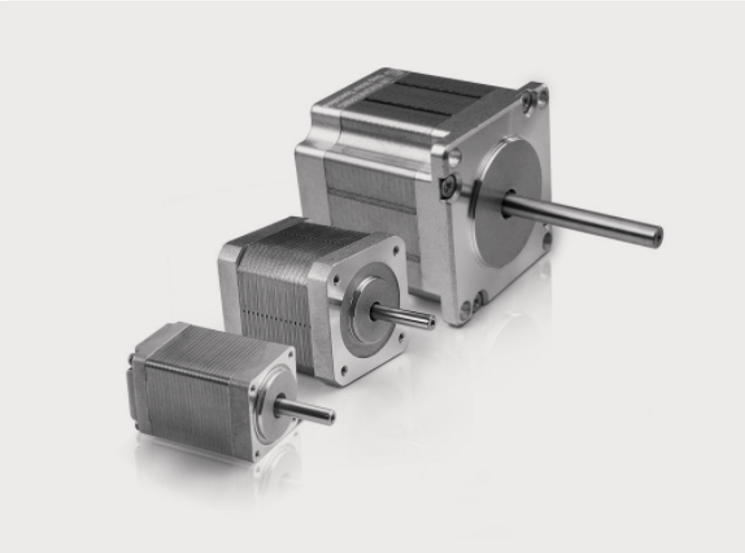

Vacuum compatible motors, such as our 211 Series (NEMA 11), 4118 Series (NEMA 17), and 5718 Series (NEMA 23) motors, manage outgassing through our proprietary motor assembly process designed specifically for vacuum motors. By using low-outgassing materials during the manufacturing process, our products also reduce the number of contaminants that are able to enter the system.

LOOKING FOR REPRESENTATION?

Product & Services Suppliers (Principals) looking for representation.

REP OWNERS READY TO RETIRE?

If you are a retiring representatives seeking an exit strategy,

Let's Talk!